Run Your Car on Wood!

Prefer watching to reading?

You can now learn about Woodland BIO's mission to create a circular economy by developing sustainable fuels through video 📹 on our new Media page!

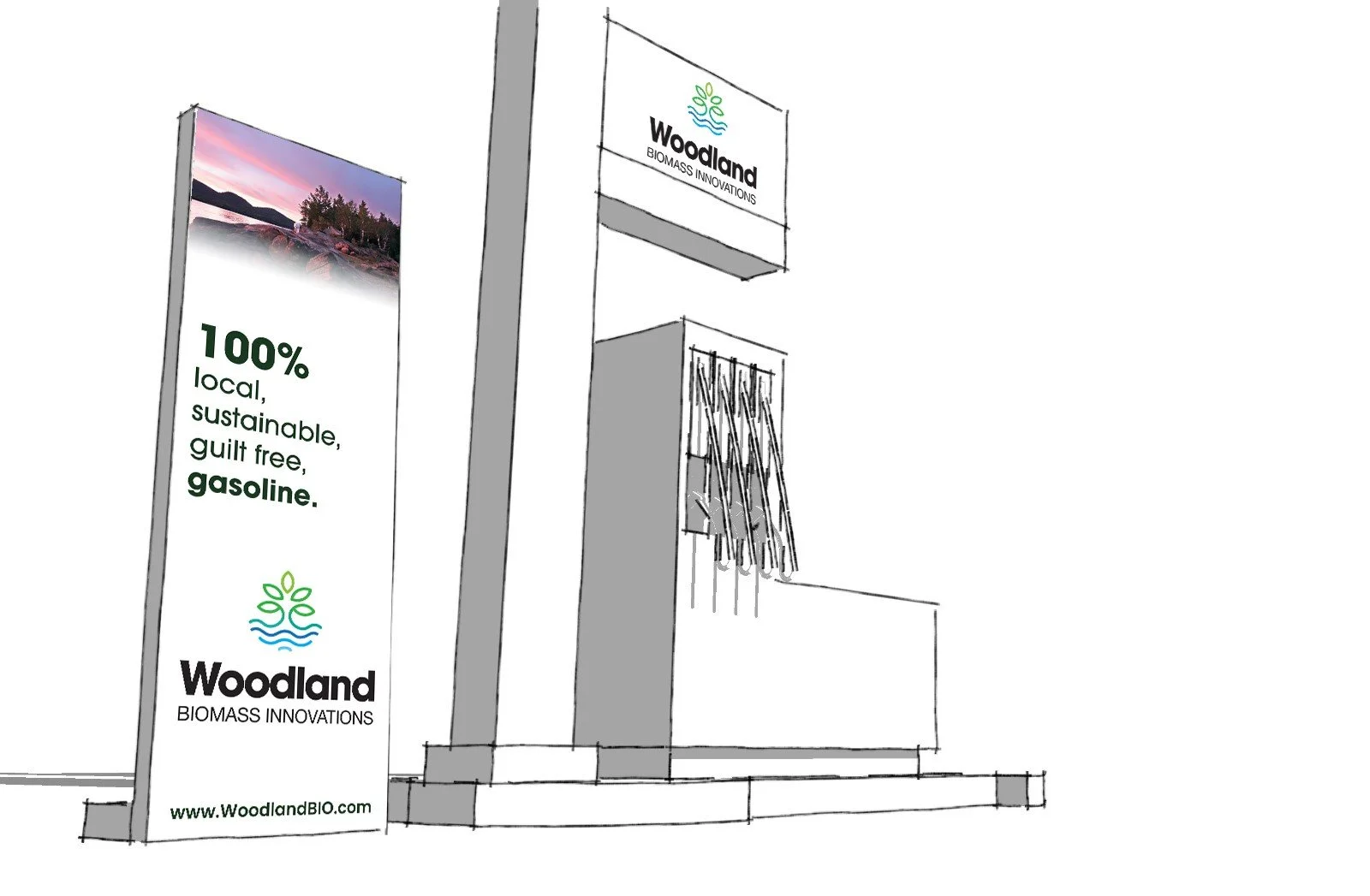

Creating sustainable pathways for fuels.

The pilot plant is designed to convert dirty wood chips, made from low-grade materials, into gasoline that is chemically identical to existing fossil fuel sources, meaning that it will work with our current vehicles and infrastructure. This approach will allow us to immediately start reducing carbon impact from transportation, without the need for environmentally and financially costly switches to modes of transportation and distribution.

The scale of the initial Woodland BIO system was calculated to be able to undercut the existing price of fossil fuel gasoline. In other words: Woodland BIO gasoline will cost less than current gasoline at the pump, and customers will save money by switching to this locally sourced and sustainable option.

Biochar, the new wonder material.

Biochar is a versatile product made up of pure carbon left over from a variety of processes that involve biomass. There are many environmentally beneficial uses for this ‘wonder’ material, ones that involve sequestering that carbon in the ground or construction materials, helping to reduce the carbon footprint of everything coming out of the Woodland BIO systems.

A Stable Long-term Investment

Woodland BIO is currently seeking investors, find out how you can get involved to help bring this mission-oriented project to life! We have a detailed project prospectus and presentation to help you make an informed decision.

Improving Forest Ecosystems

The material that will be fed into the first Woodland BIO facility can be described as low-grade woody biomass. Pennsylvania is known for its high-value saw timber and wood products, however, these materials only account for a fraction of the materials found in the forest. In order to harvest sustainably, low-grade materials such as smaller trees and less-desirable species must be harvested to make room for beneficial regrowth.

In many areas, there are not many outlets for the low-value/quality material that is also in the forest. Without robust markets for this material, or “low-grade utilization,” forest health can decline. Woodland BIO plans to create an outlet for this low-grade material which will then result in healthier forests while supporting a more sustainable and renewable supply chain for all forest products.

Supporting the forest products industry and improving forest health for the next generation are top priorities for organizations like the Pennsylvania Forest Products Association and the Pennsylvania Department of Agriculture. Woodland BIO has relied on their guidance in developing our plan for a robust and profitable market for the oversupply of low-grade material. Given the opportunity to create sustainable transportation fuels out of the very material that is in need of outlets to improve forest health, these organizations were eager to provide assistance and support.

A Pennsylvania Focus

Woodland BIO connects three of Pennsylvania’s most significant industries into one project: Energy, Agriculture, and Manufacturing.

The proposed site in Tioga County, PA, is well located for access to key markets for supply and distribution. A relationship with local government agencies has been established to provide material support in evaluating properties and financing the creation of the first Woodland BIO facility, which would bring long-term sustainable growth and jobs to the county.

This would include directly 50-100 jobs available at the facility, as well as hundreds of knock-on jobs created in adjacent industries, in everything from logging to food & beverage.